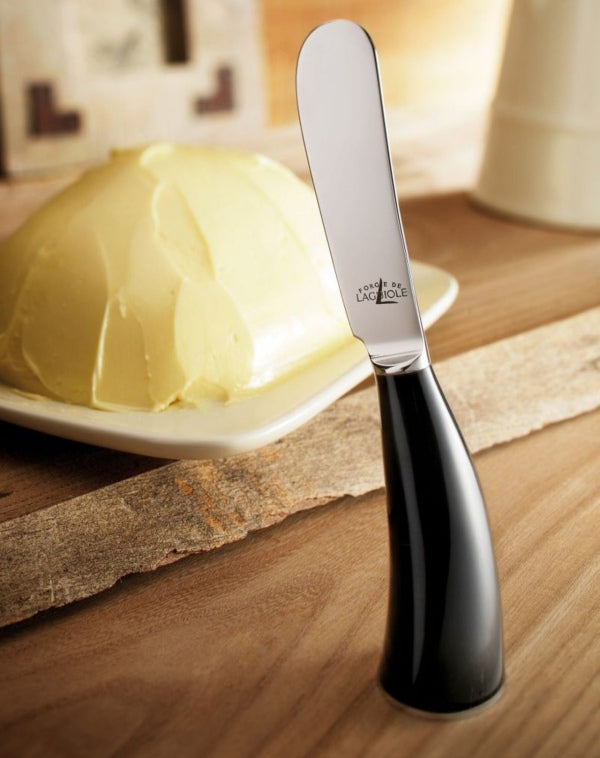

In an age dominated by mass production and automation, the art of traditional craftsmanship holds a revered place. Nowhere is this more evident than in the creation of a Laguiole knife—a symbol of precision, dedication, and artistry. The philosophy of "One Artisan, One Knife" encapsulates the unique process that sets these knives apart from the rest.

The Art of Crafting a Laguiole Knife

Creating a Laguiole knife is not a mere task; it's a labor of love and a testament to generations of expertise. Unlike factory-made knives that are churned out by the thousands with little care, each Laguiole knife is a masterpiece, handcrafted by a single artisan who imbues it with personal skill and pride.

Over 100 Steps to Perfection

Completing a single "1 piece" Laguiole knife requires more than 100 precise operations. This meticulous process captures the essence of traditional French cutlery craftsmanship, with each step executed with exacting attention to detail.

- Handmade Assembly: When a Laguiole knife claims to be "handmade," it signifies that one skilled artisan assembles, shapes, and finishes the knife. However, they do not forge the blade or bolsters themselves; rather, they gather raw components and craft them into a cohesive whole.

- Collector Series Mastery: The collector series of Laguiole knives takes craftsmanship to another level. Here, the spring and bee are entirely hand-chiseled—an intricate process demanding approximately an hour of dedicated work for each piece.

Quality Assurance

Once assembled, a Laguiole knife undergoes rigorous inspection by a foreman who ensures it meets high-quality standards. Any imperfections are meticulously addressed, and the knife is polished to achieve a flawless finish. Only then is it labeled, ready to become a cherished possession for its owner.

The Contrast with Mass Production

Factory production techniques starkly contrast with the craftsmanship of a Laguiole knife. In mass production, the process is fragmented, with each untrained worker performing a single task before passing the knife along the assembly line. This fragmentation erodes any sense of ownership or pride in the final product.

- Machine Reliance: Mass production relies heavily on numerically controlled machines, sidelining skilled artisans. This often results in inferior products that lack the artistry and quality of handcrafted knives.

- Ethical Concerns: Many "bargain" Laguiole knives are mass-produced under questionable conditions in countries like China or Pakistan, sometimes using child labor. It's a stark reminder of the ethical considerations consumers must weigh when purchasing cutlery.

Awareness and Responsiveness

Even in France, some lower-quality Laguiole steak knives surf the market, often unbeknownst to buyers who lack knowledge about the intricacies of Laguiole craftsmanship. It's not malice but ignorance that perpetuates this cycle. If top-tier retailers understood the nuances of authentic Laguiole knives, they would undoubtedly reconsider their offerings.

Conclusion

The "One Artisan, One Knife" philosophy is more than just a slogan—it's a commitment to maintaining the integrity and tradition of knife-making. Each Laguiole knife represents a personal connection between craftsman and craft, a relationship that ensures every piece is unique and of the highest quality.

For those who value tradition and artistry, opting for a handcrafted Laguiole knife is not simply a purchase—it's an investment in a legacy of craftsmanship. Consider visiting Forge de Laguiole and Fontenille Pataud collections, where each knife is a testament to the art of "One Artisan, One Knife." Explore our range today and become part of this timeless tradition.

Leave a comment (all fields required)